Few armored vehicles have inspired as much debate as the American M1 Abrams and the Soviet-designed T-72. Though often framed as direct rivals, these tanks were never built to fight the same war in the same way. Each reflects a radically different philosophy about armor, crew survivability, logistics, and how wars are actually won.

This article provides a complete, no-nonsense comparison of the M1 Abrams and T-72 - not just specifications, but what those differences mean in real combat.

At a Glance: Quick Verdict

M1 Abrams Wins

- Firepower

- Armor & Crew Survivability

- Electronics & Situational Awareness

T-72 Wins

- Simplicity & Ease of Production

- Cost & Mass Deployment

M1 Abrams vs T-72: Key Comparison Table (Quick Reference)

This table is designed to answer "which is better and why" in under 30 seconds - without oversimplifying.

| Category | M1 Abrams | T-72 | Why This Matters |

|---|---|---|---|

| Crew Size | 4 (Commander, Gunner, Loader, Driver) | 3 (Autoloader replaces loader) | Larger crews reduce fatigue, increase redundancy, and improve battlefield awareness |

| Main Gun | 120 mm smoothbore | 125 mm smoothbore | Caliber alone doesn't decide outcomes - fire control and ammo handling matter more |

| Ammunition Storage | Separate compartment with blowout panels | Stored inside crew compartment (carousel autoloader) | Directly impacts crew survivability after penetration |

| Fire Control & Optics | Advanced thermals, stabilized sights, long-range accuracy | More basic optics in older variants; improved in later upgrades | Seeing and hitting first often decides the fight |

| Armor Philosophy | Composite armor focused on crew survival | Steel/composite variants focused on compactness | Protection design reflects doctrine, not just technology |

| Engine Type | Gas turbine | Diesel | Turbine offers performance; diesel offers efficiency and simplicity |

| Fuel & Logistics Demand | Very high | Moderate | Logistics often determine how long a tank stays in the fight |

| Mobility (Tactical) | Excellent acceleration and cross-country speed | Good mobility, lighter overall | Tactical mobility ≠ strategic sustainment |

| Maintenance Complexity | High | Lower | Simpler systems are easier to keep running in austere environments |

| Training Assumptions | Highly trained professional crews | Shorter training cycles assumed | Crew skill strongly affects real-world performance |

| Unit Cost (Relative) | Very expensive | Much cheaper | Cost influences numbers, replacement rate, and doctrine |

| Doctrine Fit | Combined-arms, precision warfare | Mass deployment, attrition-tolerant | These tanks were built for different wars |

The Abrams is optimized for survivability, precision, and combined-arms warfare.

The T-72 is optimized for simplicity, numbers, and rapid replacement.

Front profile comparison: The M1 Abrams (left) features a larger, more angular profile with emphasis on crew protection, while the T-72 (right) has a compact, low-silhouette design optimized for mass production.

Design Philosophy: Two Different Views of War

The M1 Abrams Philosophy: Protect the Crew, Win the Fight

The M1 Abrams was developed during the Cold War with a clear priority: crew survival and battlefield dominance. American planners assumed that trained crews were valuable assets that could not be easily replaced. The tank was designed to give those crews every possible advantage - even if it meant higher cost, complexity, and logistical burden.

This philosophy is evident everywhere in the Abrams. It uses advanced composite armor, separate ammunition storage with blowout panels, and highly sophisticated optics and fire-control systems. The Abrams was meant to fight at long ranges, detect enemies first, fire accurately while moving, and survive even if hit.

The result is a tank that excels in high-intensity, combined-arms warfare, especially when supported by air power, logistics, and intelligence assets.

The T-72 Philosophy: Simplicity, Numbers, and Replaceability

The T-72 reflects a very different approach. Designed by the Soviet Union, it prioritized mass production, mechanical simplicity, and ease of use by conscript forces. The assumption was that tanks would be fielded in large numbers, losses would be expected, and equipment needed to be replaceable quickly.

To reduce size and cost, the T-72 uses an autoloader instead of a fourth crew member. Armor is simpler and lighter, and internal layout is more compact. Maintenance is easier, fuel consumption is lower, and production costs are dramatically reduced.

This approach made the T-72 one of the most widely produced tanks in history - but it also introduced significant tradeoffs in survivability and situational awareness. (See also: Abrams vs Leopard 2).

Design philosophy: The Abrams prioritizes individual tank capability and crew protection (left), while the T-72 was designed for mass deployment in armored formations (right).

Firepower: More Than Just Gun Size

On paper, both tanks are formidable.

The M1 Abrams mounts a 120mm smoothbore gun, firing advanced kinetic energy penetrators and multi-purpose rounds. The T-72 uses a 125mm smoothbore gun, also capable of firing armor-piercing and high-explosive ammunition, including gun-launched anti-tank missiles in some variants.

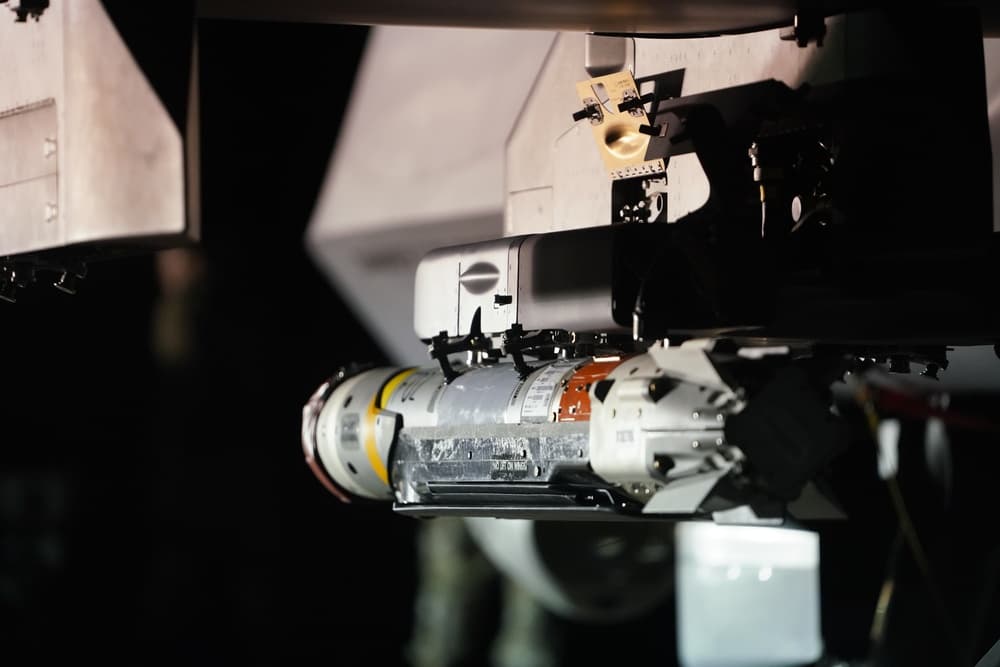

Firepower in action: Both tanks mount powerful smoothbore guns, but the Abrams' superior fire control systems give it a significant advantage in accuracy and first-round hit probability.

Where the difference emerges is fire-control and accuracy.

The Abrams features:

- Advanced thermal sights

- Stabilized fire-control systems

- High first-round hit probability at long range

- Superior night and poor-visibility combat capability

The T-72, especially older variants, relies on more basic optics and less sophisticated stabilization. While later upgrades have improved performance, the Abrams consistently demonstrates faster target acquisition and higher accuracy, particularly while moving.

Caliber is only one factor - ammunition type, barrel quality, and fire control all play critical roles. (Related comparison: 120mm vs 125mm tank guns).

In modern armored combat, seeing and hitting first often matters more than caliber alone.

Armor and Survivability: The Defining Difference

This is the most critical area of comparison.

M1 Abrams Survivability

The Abrams uses composite armor, incorporating advanced materials designed to defeat both kinetic and shaped-charge threats. Perhaps more importantly, its ammunition is stored in a separate compartment with blowout panels. If the ammunition detonates, the explosion is directed away from the crew.

This design choice has repeatedly proven its value. Abrams crews have survived catastrophic hits that would have destroyed older tanks entirely.

T-72 Survivability

The T-72's compact design places ammunition inside the crew compartment, often arranged around the autoloader. If penetrated, this can result in a catastrophic explosion - sometimes referred to as a "jack-in-the-box" effect - where the turret is violently separated from the hull.

While newer variants have improved armor and defensive systems, the fundamental layout remains a vulnerability. Crew survivability was not the primary design driver in the original T-72 concept. (Further reading: Tank ammunition storage and crew survivability).

Crew comparison: The Abrams uses a 4-person crew with separate ammunition storage (left), while the T-72's 3-person crew works with an autoloader and ammunition stored in the fighting compartment (right).

Survivability Layout: Ammunition Placement (Simplified)

Mobility and Logistics: Power vs Practicality

The Abrams is powered by a gas turbine engine, providing exceptional acceleration and smooth power delivery. This gives it excellent tactical mobility, especially over rough terrain.

However, the turbine consumes large amounts of fuel and requires extensive logistical support. Fuel convoys, maintenance crews, and recovery vehicles are essential to sustained operations.

The T-72 uses a diesel engine, which is simpler, more fuel-efficient, and easier to maintain in austere conditions. This makes it well-suited to prolonged operations where logistics are limited.

Engine comparison: The Abrams' gas turbine (left) provides superior power but high fuel consumption, while the T-72's diesel (right) offers better fuel economy and simpler maintenance.

| Aspect | M1 Abrams | T-72 |

|---|---|---|

| Engine Type | Gas Turbine (1,500 hp) | Diesel (780-1,000 hp) |

| Fuel Consumption | High | Moderate |

| Maintenance Complexity | High | Low |

| Field Serviceability | Requires specialized support | More field-serviceable |

In short: Abrams offers superior performance with a higher logistical burden; T-72 provides lower performance with easier sustainment. (Related analysis: Gas turbine vs diesel tank engines).

Sustainment Reality: Logistics Burden Index (Relative)

Crew, Training, and Human Factors

The Abrams operates with a four-person crew: commander, gunner, loader, and driver. This allows tasks to be distributed, reduces fatigue, and improves battlefield awareness.

The T-72 uses a three-person crew, relying on an autoloader. While this reduces manpower requirements, it increases workload and limits redundancy if a crew member is injured.

Western doctrine emphasizes intensive training, situational awareness, and coordination. The Abrams is built around this assumption. The T-72 assumes shorter training cycles and simpler operation, prioritizing quantity over individual crew effectiveness.

Real-World Combat Performance

The Abrams has seen extensive combat use, particularly during the Gulf War and subsequent conflicts. In these engagements, it demonstrated overwhelming superiority against older Soviet-designed tanks, often engaging and destroying enemy armor at ranges where return fire was ineffective.

The T-72 has been used widely across multiple conflicts and operators, with performance varying significantly depending on training, maintenance, and variant. Modernized versions perform better than early models, but losses in recent conflicts have highlighted persistent vulnerabilities, especially against advanced anti-tank weapons.

The Gulf War demonstrated this asymmetry vividly, with Abrams crews engaging T-72s at ranges where return fire was largely ineffective. (Contextual comparison: Abrams vs Iraqi armor in the Gulf War).

It is important to note that outcomes depend heavily on how tanks are used - not just on design alone.

Cost, Production, and Global Use

The Abrams is expensive to build, operate, and maintain. Its strength lies in quality over quantity.

The T-72 is relatively inexpensive, widely produced, and operated by dozens of countries. Its global spread reflects its affordability and adaptability, even if performance varies.

This difference underscores the core contrast: elite capability versus mass availability.

Doctrine Fit Matrix: Capability vs Mass Deployability

Final Verdict: Not a Simple "Winner"

The M1 Abrams and T-72 are not simply better or worse versions of the same idea. They are answers to different strategic questions.

M1 Abrams

Excels in survivability, precision, and modern combined-arms warfare. When supported by logistics and trained crews, it is among the most lethal tanks ever built.

T-72

Reflects a doctrine where simplicity, numbers, and ease of replacement matter more than individual vehicle survivability. In that context, it has achieved enormous global impact.

Understanding these differences is essential to understanding modern armored warfare itself.

M1 Abrams vs T-72: Frequently Asked Questions

These are the most common questions people search when comparing the M1 Abrams and the T-72.

Could a T-72 destroy an M1 Abrams?

Yes - under the right conditions. No tank is invincible. However, the Abrams' armor, sensors, and crew protection significantly reduce the odds in most direct engagements.

Why does the T-72 only have three crew members?

The T-72 uses an autoloader to reduce crew size, tank height, and production cost. This simplifies logistics but increases crew workload and reduces survivability if the tank is penetrated.

What are blowout panels, and why do they matter?

Blowout panels vent ammunition explosions away from the crew. This design choice dramatically increases crew survival compared to tanks where ammunition is stored inside the fighting compartment.

Is the Abrams too heavy for modern warfare?

The Abrams is heavy, but that weight supports armor, survivability, and advanced systems. The tradeoff is higher fuel use and logistical complexity.

Which tank is better in urban combat?

Urban combat depends more on infantry support, training, and coordination than the tank itself. The Abrams' sensors help, but no tank performs well alone in cities.

Why is the Abrams so expensive compared to the T-72?

The Abrams prioritizes advanced electronics, armor, crew safety, and performance. The T-72 prioritizes affordability and mass production.

Do modern T-72 variants fix the survivability issues?

Upgrades improve protection and sensors, but the fundamental internal layout remains a limitation compared to designs with separated ammunition storage.

Which tank is easier to maintain in poor conditions?

The T-72's diesel engine and simpler systems are generally easier to maintain without extensive logistical support.

Is it fair to compare these tanks directly?

Only with context. They were designed for different doctrines, assumptions, and types of war.

Does training matter more than the tank itself?

Often, yes. Well-trained crews consistently outperform superior equipment used poorly.

Why does the Abrams dominate Western narratives?

Because it has been used in conflicts where doctrine, training, air superiority, and logistics favored it heavily.

Which tank wins overall?

There is no universal winner. The Abrams excels in survivability and precision warfare; the T-72 excels in simplicity and large-scale deployment.